Comprehensive Guide to Reefer Container Shipping

Planning is crucial for fresh goods logistics. Even if a company has built the perfect production line, it still cannot guarantee the quality of the product delivered if it does not stay fresh on its way to market. Therefore, for product segments with short shelf life, their supply chains must focus on the best way to transport them safely in order to minimize hassles.

Know Your Cargo

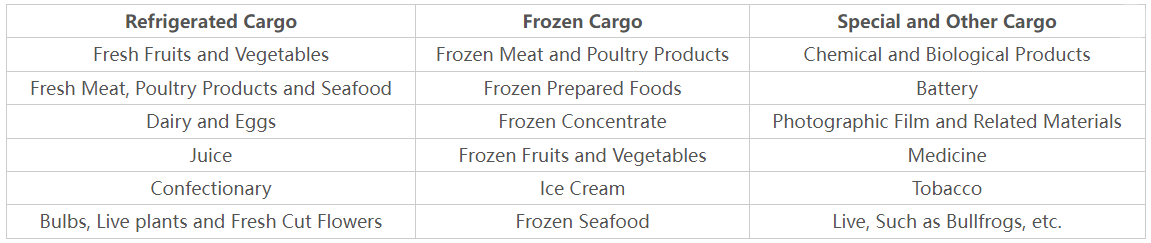

Freshness is the most important goal in the shipping process. Fresh commodities need to be transported under optimal conditions to ensure that they reach their destination in the best possible condition. Fresh commodities can be broadly classified as:

Refrigerated Cargo

Refrigerated cargoes are commodities that need to be transported in an environment above the critical freezing temperature of the goods. Some refrigerated cargoes have different product characteristics and factors that affect their shelf life and have higher requirements for freshness. Other commodities have a relatively short shelf life and require close attention during transport.

Reefers can detect temperature with a supply air sensor and, in general, automatically control the temperature to within plus or minus 0.5°C (0.9°F) of the set temperature or more precisely.

Refrigerated cargo includes the following types:

- Fresh fruits and vegetables

- Fresh meat, poultry products and seafood

- Dairy products and eggs

- Fruit juices

- Sugar-based foods

- Bulbs, live plants and fresh cut flowers

Temperature

Temperature is the most important factor in maintaining freshness and quality of produce because the rate of respiration is directly proportional to the rate of deterioration, which increases exponentially with increasing temperature. In general, for every 10°C (18°F) increase in temperature, the rate of deterioration increases by a factor of two to three.

Maintaining the optimal temperature during cold storage and transportation maximizes the product freshness and quality of the product.

This is because optimal temperatures can:

- Reduce respiration

- Slow down water loss and wilting

- Prevent spoilage caused by bacteria, fungi and yeasts

- Slow down undesirable growth (e.g. germination)

Maintaining a stable temperature is critical, as too high or too low a temperature will result in undesirable consequences.

Exposure to bureau temperatures will:

- Accelerate water loss

- Generate ethylene

- Produce diseased organisms

- Affect the physiological state of the product

- Cause uneven ripening, surface blackening and decay Exposure to cold temperatures can cause

- Cold damage or frostbite

- Denting or flabbiness of the surface

- Discoloration

Frozen Cargo

Generally speaking, frozen goods are commodities or food products that need to be transported and stored at -20°C (-4°F). - 20°C is the optimum temperature to prevent spoilage of produce and to prevent the growth of diseased organisms.

Some frozen goods need to be shipped at temperatures below -20°C (-4°F) to maintain their quality, texture and flavor. Shipments with high fat content, such as ice cream and surimi, should be shipped at -26.1°C (-15°F) or lower.

Low temperatures allow the quality of frozen foods (e.g., odor, flavor, texture, appearance) to be preserved and protected from spoilage. However, the temperature of a frozen shipment can only be properly controlled if the product is properly frozen, packaged and loaded for transportation requirements.

Types of frozen cargo include:

- Frozen meat, poultry and seafood

- Frozen Prepared Foods

- Frozen concentrates

Key factors affecting the transportation of frozen cargo

Freezing

Freezing is an effective means of preserving the quality of frozen foods because it inhibits microorganisms, slows down most enzymatic activity and slows down the oxidation process. Food should be completely or almost completely frozen. Foods that are not frozen at the core, or only partially frozen, will experience deterioration in texture, color, flavor and other attributes of the product.

In general:

- Fast freezing results in better product quality

- Slow freezing results in the formation of large ice crystals, which can cause cell wall breakage and result in flabby products

Thawing

Nothing is more deadly to frozen foods than repeated freezing and thawing. Proper temperature control is critical, as thawing due to temperature fluctuations can be damaging to the product.

E Packaging

Proper packaging and sealing films protect most foods from freeze spots (unsightly appearance and nutritional loss due to surface water loss), bacterial contamination and oxygen. Packaging materials should not only prevent the penetration of water vapor and oxygen, but also keep out volatile odors and substances.

Pre-cooling

Proper pre-cooling of containers used for transporting frozen goods helps to prevent:

- Surface thawing

- Frozen spots

- Surface condensation

As part of quality control procedures, frozen cargo is required to be loaded at a temperature of 15°F (- 9.4°C) or lower.

Stacking

Frozen cargo should always be stacked as a solid unit so that air can circulate around the edges of the cargo. When stacking in containers with internal flat sides, a slightly loose stack is necessary to promote air circulation, as overly tightly packed cartons may cause localized temperature increases that can lead to problems.

Ventilation

In all refrigerated shipments, fresh air vents must be tightly closed and sealed at all times.

Special and Other Cargoes

Non-food products that require temperature and/or humidity protection during transportation are classified as such. In order to maintain product quality, all special handling requirements for packaging, stowage, temperature and humidity management of such shipments must be strictly adhered to.

Special and other cargo types include:

- Chemical and biological products

- Batteries

- Tobacco products

- Medical equipment and supplies

Chemical and biological products such as medical supplies, photographic materials, cosmetics, chemicals and synthetic resins are more delicate than some fresh goods and must be given the utmost care.

The following factors usually need to be considered when shipping such goods:

Temperature Management

These types of products are extremely sensitive to temperature changes. If the temperature is not maintained within the specified range, chemical reactions may occur. All stages, from pre-cooling to packaging to loading, need to be properly monitored.

Pre-treatment Before Shipment

Products that are particularly vulnerable to damage are given additional safety measures to ensure smooth delivery. Hygiene To prevent bacterial contamination of medical products, cleaning procedures are adopted at every stage of transport.

Packaging and Stacking

Packaging specifications vary according to the characteristics of each product, and some products may even require special packaging. In addition, due to the fragile nature of these products, stacking operations are more critical than usual.

Product Compatibility

Most special and other cargoes cannot be shipped in the same container. As long as you follow the manufacturer's guidelines, you can rest assured that your product will be in the hands of our trained staff who will conduct the necessary research to ensure the safety of your shipment.

Packaging

All packaging must be properly designed, constructed and loaded to protect the product.

- Protection from rough handling: Packaging must withstand a wide range of handling and environmental conditions, including those encountered during inventory, sales and distribution. Poorly designed cartons are more likely to collapse under rough handling and high humidity conditions.

- Stacking Strength: Cardboard boxes must be designed to withstand the weight of other stacked cartons. Overloading and overstacking can result in damage to the carton and its contents.

- Protection from moisture loss: Most packaging must be able to withstand exposure to high relative humidity during transport and distribution.

- Auxiliary temperature management: A properly ventilated refrigerated cargo carton promotes air flow inside the container. The top and bottom of the carton must be ventilated to allow air to flow up through the cargo.

Loading

Proper loading is necessary to ensure the air flow required to achieve the set temperature. Key factors in maximizing post-harvest shelf life include having a clear loading plan and understanding how loading patterns affect air flow in the container. For all cargo loading and placement, it is important to cover the entire bottom of the container with a sump, box or other material and to ensure that the entire cargo does not rise above the red line.

Refrigerated Cargo

Such as fruits and vegetables, generate heat by breathing. Therefore, it is essential to allow a lot of circulating air to circulate between the goods (not just around them) to better reach all the goods. Refrigerated products need to be stacked or piled into a solid unit with no gaps between the goods and preferably with the ventilation holes aligned to promote air flow (vertical flow) through the goods at the bottom of the reefer. Sometimes it may be necessary to reinforce a refrigerated shipment to keep it stable during transport. In such cases, we recommend the use of reefers equipped with cargo tie-downs and strapping devices.

Frozen Cargo

should always be stacked as a solid unit with no gaps between packages or pallets. In addition, air must be able to circulate around the perimeter of the load. It is essential to ensure that air can circulate around the bottom, top and perimeter of the load. When stacking cargo using inner flat-sided containers, a slightly looser loading pattern allows for even circulation of cooling air around the cargo, ensuring that any heat that penetrates the container does not reach the cargo.

Composition of the refrigeration system of the reefer container

All refrigerated containers require specific components to help circulate air, dissipate heat and control the temperature of the goods. Most refrigeration units have a surplus of cooling capacity to maintain product temperature.

Refrigeration units consist of the following components:

- Compressor

- Condenser/Fan

- Evaporator/Fan

- Expansion valve

- Temperature controller

- Supply Air Sensor

- Return air sensor

- Humidity sensor

Reefer Container Shipping from China to USA / Canada / Southeast Asia

STU Supply Chain as a leading freight forwarder in China. We are licensed NVOCC, FMC, and WIFFA. We have the advantage reefer container shipping. We offer sea shipping of your refrigerated cargo at a controlled temperature in reefer container. We partner with many shipping carriers, such as Wan Hai. We can get the competitive rates and stable shipping space. We offer Shipping Routes for USA, Canada and Southeast Asia, exporting a wide range of goods. Welcome to inquire, you can contact us to get freight quote.

From STU Supply Chain: https://stusupplychain.com/comprehensive-guide-to-reefer-cntr-shipping.html

Comments

Post a Comment